Do These 12 Things to Safely Use Power Tools

I completely understand the fear of power tools. It’s the fear of not knowing exactly what to do with each tool. But it’s also the fear that even once you learn how to use each tool, you’re afraid you’ll do something stupid (or something you just didn’t realize) that will cause you to lose an eye, a finger, or a limb.

I get it. I really do.

But while power tools can be scary and the threat of injury is real, there are 12 things that you can do (no matter what the power tool is) that will keep you safe, with your eyesight, digits, and limbs. Let’s jump into them right now!

Click here to save these tips on Pinterest.

Listen to This Episode

Why People Are Afraid of Power Tools

Recently I asked my audience in a survey, “What’s your biggest challenge when it comes to power tools?” and I got a bunch of answers–over 400 responses, actually! But there were a couple of terms that kept coming up:

- Fear

- Scared

- Hurt

- Safe

- Afford

- Cost

- Space

- Heavy

The list goes on and on, but the most serious ones to me were “fear,” “scared,” and “hurt.” I dug a little deeper to find out what exactly about power tools they were most fearful and scared, and it came down to the following things:

1. Fear of Accidents

You guessed it: fear of accidents was more worrisome for my audience. Most of my readers like yourself don’t have much experience of using tools outside of a sander and a power drill (two very important tools, don’t get me wrong–but neither of those can cut wood!). To be a true DIYer, you’ll need power tools that can cut, and with it, brings the fear of injury. I get it. I still don’t like and refuse to use either of the table saws that I own because they’re literally the most dangerous tool (I mean, we all know that you’re not a real shop teacher until you’ve lost a few fingers, eh??).

Specifically, people are afraid of losing an eye, a finger, or a limb when it comes to using power tools. While I definitely feel that anxiety regarding the table saw, I think the risk of those things happening with other cutting saws isn’t quite so worrisome once you’ve got the basic safety down-pat (which is what we’re covering in this post!).

2. Fear of the Size of the Power Tools

The next thing that people mentioned regarding fear of power tools is the size of the tool. Many of my audience is older women (at least, blog readers, that is. My YouTube audience tends to be a bit younger and more diverse between men and women).

Being older, having a lack of strength is more common. And with that comes the fear of dropping the tool, or the physical limitation of simply having smaller hands.

While there are no brands that I know of made specifically for women, I will say that the RYOBI brand is not only inexpensive compared to other brands, but I also find them to be easier and less intimidating to handle.

3. Fear of Making a Mistake

Lastly, but definitely not least, the biggest fear that people have is that they’re going to totally destroy their project. Because they don’t know how to cut wood, they’re afraid that they’ll cut it incorrectly and fail.

This fear is definitely understandable, too, which is why I always do a test board before I cut into my “real” project. Test boards are perfect for practicing on until you feel confident that you know how to handle a tool.

(PSST! Want to learn how to use power tools? I’m putting together a power tools course that will teach you how to safely and accurately use the most common power tools, including which tool to use and when, and how to use them! Sign up here to receive more info as soon as it’s available!).

Okay, let’s jump into these tips right now!

How to Overcome Your Fear of Power Tools

While there are some things that are specific to each tool, there are some general guidelines that will help to ease the fear of using power tools.

TIP #1: Never Rush

Most people that have accidents, it’s because they rushed and got sloppy, or skipped safety protocols, which we’ll talk about in a moment.

This is how you have seasoned woodworkers or contractors (or experienced DIYers) injure themselves because they were rushing. You should never rush through any cut. Take your time and follow the safety protocols for each tool, without taking any shortcuts. NO.MATTER.WHAT.

TIP #2: Always Wear Safety Glasses

One of the biggest fears with using power tools is “losing an eye, a finger, or a limb.” Well, if you’re wearing safety glasses at all times, you definitely won’t lose an eye. It’s that people get lazy and decide to cut this one board….or just do this one little thing “real quick” before something happens. If you make it a point to always wear safety glasses, then your eyes will be just fine.

TIP: Look for safety glasses that have the Z-87 rating on them. These are specifically tested and designed to withstand even nails coming at your eyes from an accidental firing of a nailer. Your regular eye glasses aren’t designed for this, so be sure to always have the appropriate safety glasses. They do make larger ones that can fit over your regular seeing eye glasses.

TIP: If your safety glasses fog up, use shaving cream to de-fog them. It doesn’t last forever, so you will have to do it every so often, but it works well. Keep some in your shop. Or you can buy anti-fog glasses, like my favorite anti-fog ones from Milwaukee.

BONUS TIP: Always Wear a Dust Mask, too!

As a newbie, it’s tending to skip a dust mask when you think the air is clear. But cutting wood creates a lot of dust that can be invisible to the naked eye. If you’re working around sawdust, mask up.

TIP: Use a box fan with an HVAC pleated filter taped to the back of it and use this hack to trap some of the dust in the air when using power tools. An air filtration system is best, but if you don’t have one, this tip works well and is commonly used by woodworkers, even for larger particles created while cutting.

TIP #3: Never Wear Flip Flops

Actually, don’t wear anything that could cause a broken toe or a cut toe when using power tools, including your cute, fluffy slippers. This is a common mistake that DIYers make (especially newbies). It’s just not something you think about, but it serves you well to think about those tootsies.

I highly recommend getting some affordable steel toe or composite toe boots.

I’ve dropped wood on my toes before, and oh man, it doesn’t feel good at all! But it’s not just about dropping wood, but dropping tools, power tools, or anything in a shop that could tip over and break or cut your toes.

One of my sponsors, Ariat, had sent me some awesome work boots with composite toe and when I’m working outside or around heavy wood, I always wear these boots. Love them! You can find similar cute Ariat composite boots here.

TIP #4: Always clamp or support your wood or material.

I won’t lie when I tell you that I have used my hand to “clamp” something down before cutting it. That was something, as a newbie, I thought was okay, as long as it seemed secure and wasn’t a “big cut.” But you should never use your hand to clamp something. Rather, you should use a standard clamp to clamp your wood or material to a sturdy workbench or table. (I like this mobile workstation for a secure workbench and I like Pony Jorgensen clamps).

Now, let’s talk about support.

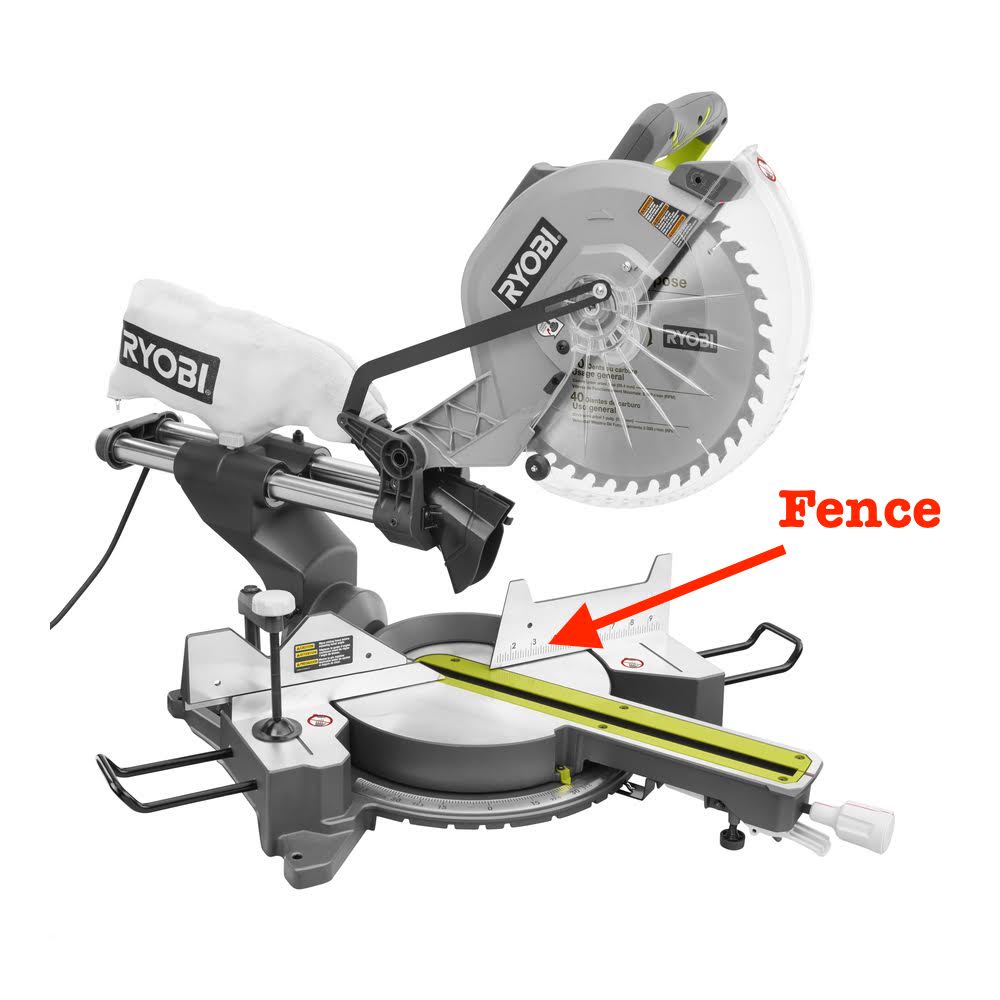

On a miter saw, there is a fence. The fence is the metal vertical part of a miter saw (usually with numbers for measuring, if needed) and this fence is what holds the materials in place, stabilizing it so it doesn’t move at all while you’re cutting. It provides a lot of support for your wood or material.

In fact, if you were standing in front of a miter saw, the blade is moving in the direction towards you. That direction essentially cuts into the wood, pulling the wood tighter to the fence, which is a good thing.

On a table saw, there is a fence, as well, and that fence is important when making rip cuts that go with the grain of the wood. The fence is important in keeping the material steadily going with the blade cutting it, while your hand is keeping pressure on the wood against the fence. (NOTE: When making a cross cut, against the grain of the wood, the fence isn’t used because the fence could pinch the wood and cause kick back).

(That’s one of the nuisances that you learn as you go, about the table saw).

However, in general, fences are your friend on a miter saw and a table saw.

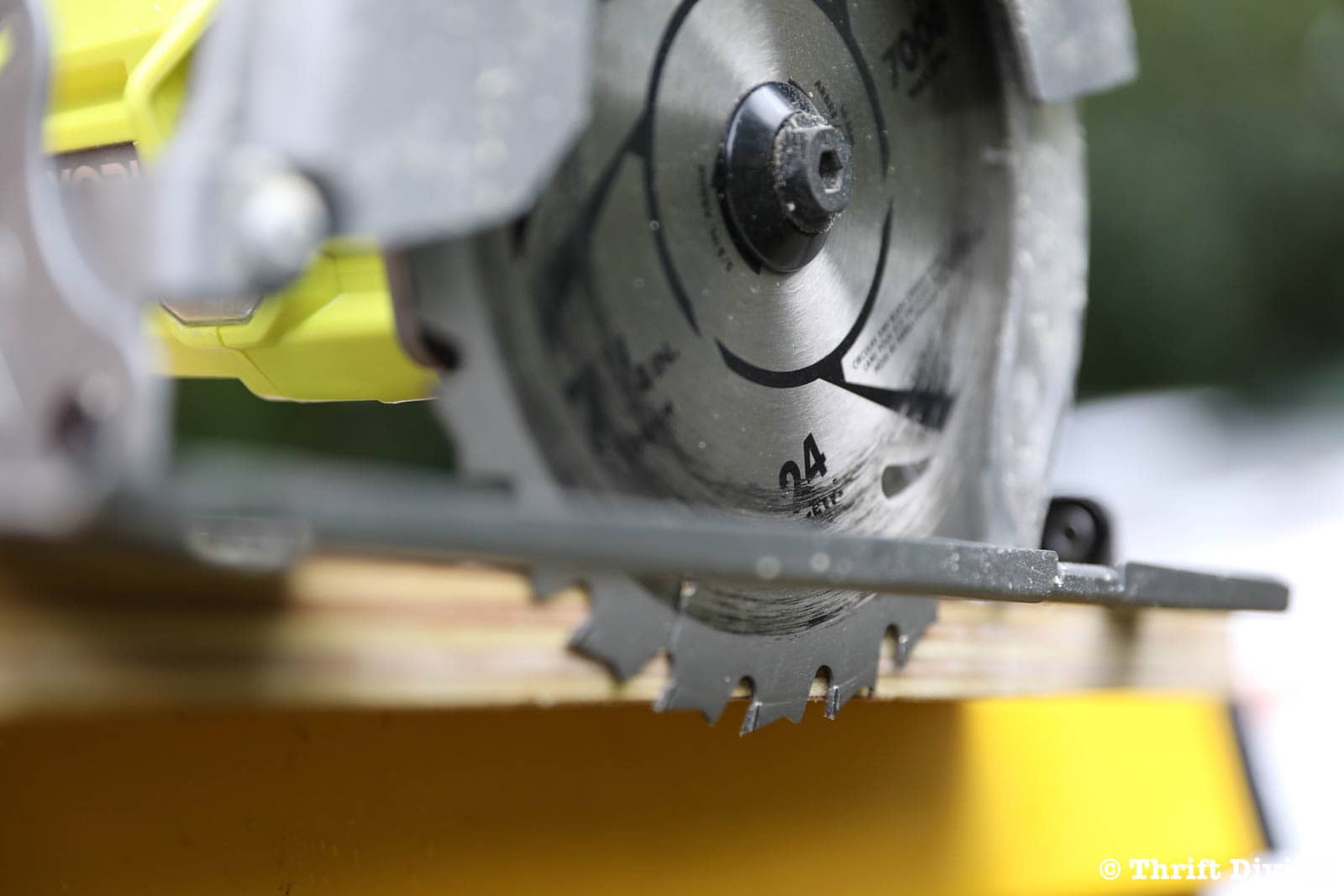

On a jigsaw and a circular saw, however, they don’t have fences. Instead, they have bases. That base is the flat metal part of the tool that sits on the wood or material as it’s being cut.

Remember that for these tools, always keep the metal base sitting on your material while cutting. It does the same thing as a fence, keeping the wood and material stable while it’s being cut.

If you don’t have the metal base sitting flat on your material while being cut, there is nothing to stabilize the wood or your power tool, and the tool could jump or kick back.

So, as a rule, remember this: Always keep the base flat and supported on the material you are cutting for the safest cuts.

Same with a circular saw; its wide base creates a stable cut while cutting. In the picture below, notice how the circular saw base widest part is sitting supported on the wider part of the board.

Also notice that the part that is being cut off is allowed to freely drop after it’s cut (aren’t you glad you have composite toe boots??). 😉

Click here to learn more about how to safely use a circular saw.

TIP #5: Check Your Blades First–Would Anything Be in the Way While Cutting?

Blades are so important when using power tools. Tools like a table saw require you to check to make sure your place is perfectly straight and level, but other power tools aren’t quite so tedious. Most tools will have a setting on them to let you know that your blade is straight and even, cutting at a 90-degree level (although most tools have blades that can be leaned to the side in order to do a slanted bevel cut).

But for this tip, I’m not talking about checking the angle of your blade. I’m talking about making sure that nothing is in the way of your blade.

For example, on a jigsaw, there is a long blade that moves up and down and cuts the wood. You’ll want to make sure that the part that you’re cutting is hanging free off the side of the table, properly clamped down and not moving. You wouldn’t want to cut into your table or find that there is something else under the wood hanging off the table that could get in the way.

NOTE: Cutting something and not being mindful of what’s under your wood, potentially hitting something else, could cause your power tool to kick back and jump in your hands.

Same for the circular saw. And even the drill. Whenever you’re cutting or drilling in to, make sure that it’s properly clamped to a table and the area that is being cut is hanging off the side of the table (or has a piece of sacrificial wood underneath to avoid cutting your table. (By the way, using a sacrificial board under your project wood when drilling helps you to avoid tear-out on the underside of your wood).

On a circular saw, depending on the thickness of your wood, you will have to adjust your blade to make sure it fully clears the material, with just about 1/4″ of the blade deeper than the material you’re cutting. In other words, let’s say you’re cutting a 3/4″ piece of plywood. The circular saw blade would be adjusted so that the tip of the blade would just cut 1/4″ deeper through the material.

Keeping your blades cutting through the material with just the tip of the blade going a bit deeper not only keeps your blade sharp, but also prevents deep cuts in anything that could be underneath, including your fingers.

NOT that you should put your fingers under a circular saw blade. But if by some chance you reach under your wood while the blade is moving, you literally can’t do as severe of damage to your fingers, versus if your blade was all the way extended deep through your material. Make sense?

TIP #6: Run Tools at Full Speed Before Making Contact

It can seem overwhelming to turn on a power tool and run it full-speed. But that’s exactly what you should do before making a cut, before the tip of the blade ever makes contact with your wood or material.

The reason why is because once the blade is running, it can easily cut through the material the moment it touches your wood.

But if you touch the tip of a blade to the wood FIRST, and then you turn it on, you’ll make the tool jump as the blade strikes the wood, which could be very scary kickback. You could also damage your wood.

It’s less scary to run it at full speed, making sure the front edge of the base is sitting on the wood for support, and then moving the tool forward.

For a miter saw, you’d run the blade at full speed first, and then bring the blade down onto your material. It will be a clean, safe, smooth cut and you won’t damage your wood.

TIP #7: Keep Your Fingers Away From the Blade

Sounds pretty common sense, right? But it’s something to always be mindful of when using power tools. For example, on a miter saw, you never want to put your hands anywhere near the cutting area.

On a miter saw, you would keep your fingers away from any area the metal round circular area (see below). That’s the cutting area.

For a table saw, you’d use a push-stick to safely push your material through, or some other cool gadget that is made for safe passage of your wood through a table saw that keeps pressure on the wood while easily and safely allowing the wood to be cut without your fingers nearby. Check out the cool gadgets from Microjig Gripper.

For a jigsaw and circular saw, I never put my fingers anywhere near the blade. If I need to check to see where my blade is in relation to the edge of the table, I fully stop the tool, then look underneath to see where the blade is and to see if I need to rotate my work so that I can finish a cut.

I will also keep my fingers to the back of a tool if I need to help guide it or keep it straight. But never near the front or bottom of a tool.

The time when you need to be most vigilant with where your hands are is when you’re attempting to cut small pieces or to make narrow cuts.

If a piece is too small, too narrow, and can’t easily be stabilized with anything other than your fingers (and cannot be clamped securely with a clamp), then it’s not a safe cut. Don’t make it. Figure out another way to make the cut.

This is one reason I love to use a track saw. I can make small or slim cuts safely–much more safely than could be done on a circular saw, jigsaw, or a table saw. I use a Festool track saw but Kreg makes a great plunge saw and Makita makes one, as well.

TIP 7#. : Always Let the Blade Stop Before Moving the Tool or the Material

This is something I see a lot of seasoned woodworkers or contractors doing, and I can’t bring myself to follow suit: after they use a tool to complete a cut, they bring the tool up or back into position while the blade is still running.

Meaning, they’ve removed their finger from the trigger, but the blade is still moving (because it does take a moment to stop moving). Those can be times when fingers get in the way, or the blade can catch on the end of a board, or something.

I was always taught to let the blade stop moving fully and then bring the tool back into position afterwards. If you live by that rule, you’ll always be practicing the best safety!

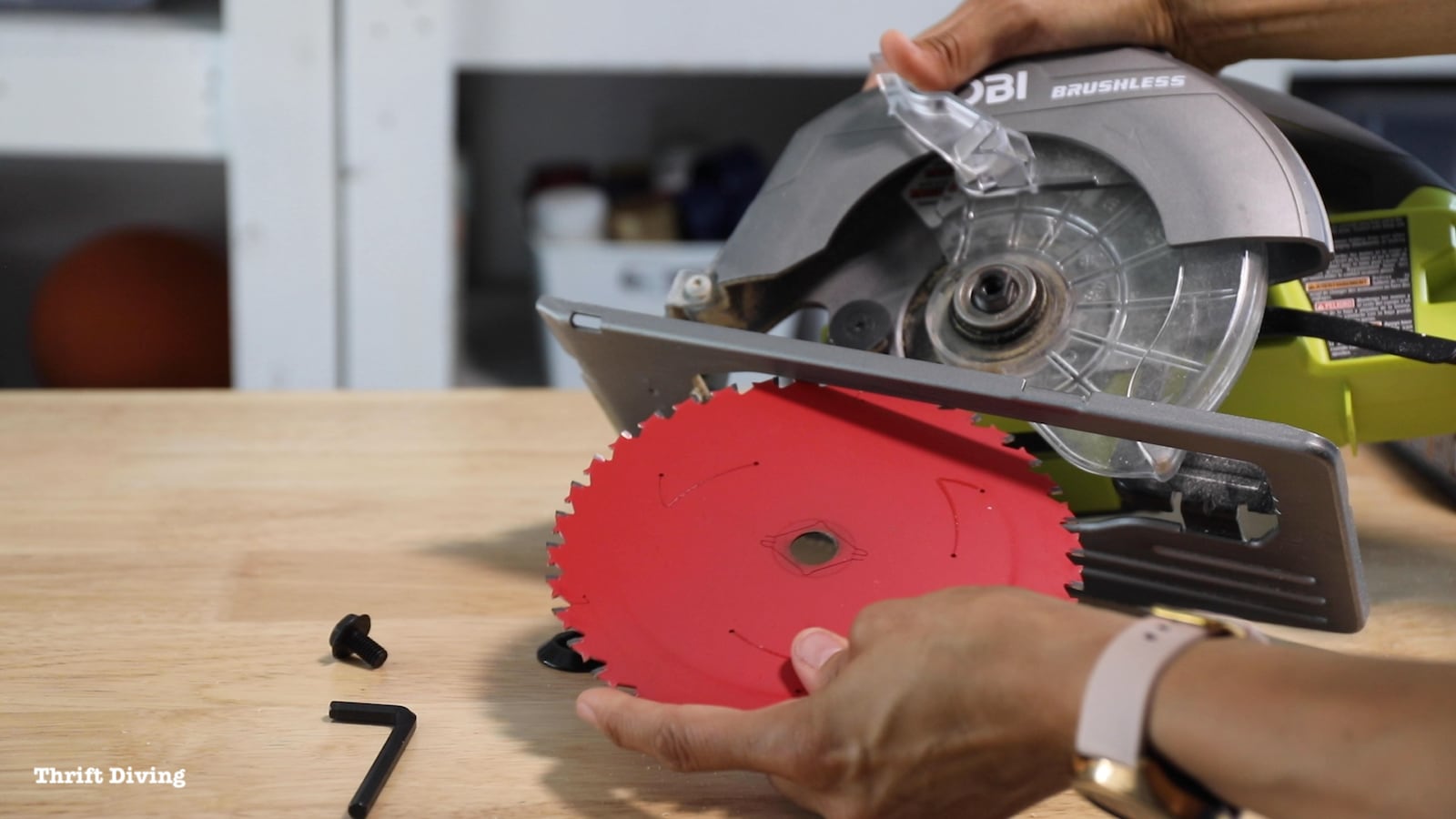

TIP #8: Always Unplug or Remove the Battery When Not in Use or Changing Blades

Another great safety tip is to always remove the battery or unplug the cord when making adjustments to the tool. Whether you’re changing a blade, or adjusting the blade, like on a circular saw and you’re adjusting the depth of the blade to cut a 2×4 now or something. Again, remember you’d set the depth to only 1/4″ below that 2×4. That small adjustment you would still want to remove the battery. I always do this, no matter what.

TIP #9: Listen to the Sound of the Tool

Sometimes the sound of a tool tells you that you’re putting it under some stress that might not be safe. Does it normally sound like “brrrrrr” but now with this cut, it shouldn’t be louder, more shrill, or sound like the blade is being pinched? Stop immediately and take a good look at your cut. Did you cut something underneath? Is the blade getting pinched? If it sounds different, stop cutting and see if you can identify the problem. This is another reason why Tip #10 is so important….

TIP #10: Avoid Distractions

I’ll admit that I love working while listening to talk radio. I get bored working in a quiet room. But I do keep the volume normal. I want to be able to hear if something sounds awkward.

TIP #11: Get Cozy with the Manual

As overwhelming as the manuals can seem, take time to read it. They have a lot of safety info in it, and reminds you of things that you may have forgotten or didn’t know was a safety issue. For example, I once read the manual of a power drill I owned. We all know how to use a power drill, for the most part. But there are some ways that people use them that aren’t really safe. For example, have you ever seen someone insert a new drill bit and to tighten it up, instead of manually tightening the chuck, they turn the tool on while holding the chuck?

TIP #12: Trust Your Gut

If something seems unsafe, it usually is. Stop and think about what makes this cut unsafe and then figure out how you can make it safer. Here are some suggestions:

- If your wood seems unstable or shaky, add extra clamps before cutting.

- If the piece is too small and cannot be clamped, try cutting a small piece off of a larger piece that can be clamped instead of trying to cut a small piece from an already-t00-small piece. If you’ve run out of material, buy more material. Sucks to spend more money when all you need is a small piece, but better to buy more material and make a safe cut than to try to use scraps and end up in the emergency room.

- If the tool sounds like it’s working too hard or squealing or sounds abnormal, stop and make sure the blade isn’t being pinched between the wood. Check out this post on How to Use a Circular Saw to learn how not to pinch your blade.

You DON’T Have to Be Scared of Power Tools

I don’t think that power tools need to be scary, but you do have to respect them. These safety tips and rules are how you navigate around your DIY workshop without fear. If you know what to do and do it the same way every time, without distraction or rushing, or ignoring your gut, you’ll be fine. 🙂

Got a question about a power tool? Leave it down below in the comments section!

Love this post? Click here to SAVE it on Pinterest!

Download the 5 freebies!

Thrift Diving inspires women to decorate, improve, and maintain their home themselves...using paint, power tools, and thrift stores! Use these 5 printables, checklists, and ebooks to get started!

Thank you for another informative blog post! I have a few power tools (10″ miter saw, circular saw, small wokx saw, etc), but I would look at them with fear. I’m excited to take your upcoming class, currently on your waitlist! Will also be upgrading my circular saw and a few other power tools, they are too old and are missing some current safety features. I also get confused about the pneumatic (airstrike) nailer – brad nailer (trim work/baseboards/smaller wood work) and finish nailer (more than 2″ wood/crown molding?). Thinking, that’s the difference!

Wow, you are decked out and ready with them tools!! LOL. You are right about the brad nailer and the finish nailer. The brad nailer uses 18 gauge (thinner) nails and is used for trim, baseboards and small things like that, just as you said. A finish nailer uses a thicker gauge of nails, like 16 gauge, for things like crown molding. You’re got it!! Can’t wait for you to join my course! Soon as this shed is at an acceptable level of “done” I am going to start recording the modules! 🙂

Me again. I just thought of something to add. A lot of older power tools, like circular saws do not have the safety features that modern tools have, such as blade brakes and finger switches to prevent accidentally turning the tool on. If you have one of these old tools, I highly recommend you throw it away and get a new one. They are dangerous!

Great point, Michael!! Tools just get safer and safer with more technology they’ve built into them, like preventing the accidental turning on of the tool. This is why it may not be the best idea to work with the hand-me-down tools from the previous generations. Just upgrade and the new tools. I almost feel this way about cars, too, especially with my oldest son just a year or so away from being a driver. I would want him to have something newer (although I hate the idea of paying for it) so that he could have the latest safety features that are on those vehicles!

This is an excellent blog!! I have been woodworking all of my life, and power tools still scare me. My great grandfather, who worked all his life in a furniture factory in the early 1900’s used to say that if you have all of your fingers, you are not a woodworker. He was missing 5 fingers total. Safety first! (OK, I do violate some of the rules)

OMG! LOL. Your great grandfather was a spitfire! Wow….missing 5 fingers! I’d love to know how many accidents comprised those 5 fingers! Interesting that you say that power tools still scare you. I think you’re right that you always have to have a healthy respect for a tool, no matter how long you’ve been using it. It comes down to knowing that the power tool can win every time if you do something wrong. 🙂